MSD Shaz Com Online

Online Learning with Gadgets

Online Learning with Gadgets

Fibreboard is one of the most adaptable materials in modern industries, blending functionality and affordability while minimizing environmental impact. Used in everything from furniture manufacturing to construction, fibreboard usability spans an impressive range of applications. But what exactly makes it so versatile? Let’s break it down.

What is Fibreboard?

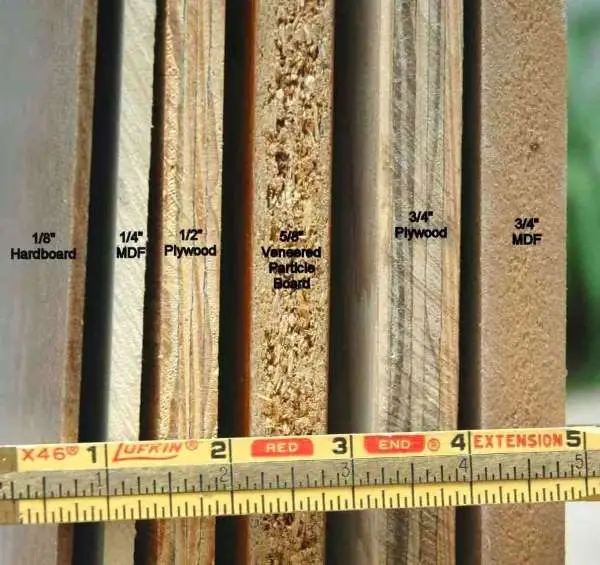

Fibreboard, also known as engineered wood or fiberboard, is a man-made product crafted from wood fibers, resin, and sometimes wax. Unlike natural hardwood or plywood, fibreboard is designed to provide consistent strength and texture without the natural imperfections found in wood.

It comes in various types, including Medium-Density Fibreboard (MDF), high-density fibreboard (HDF), and low-density fibreboard (LDF). Each type is tailored to meet specific needs, making fibreboard a go-to material for a variety of industries.

For example, MDF is known for its smooth surface and ease of machining, while HDF is more durable and dense, ideal for laminates or flooring.

Common Uses of Fibreboard

One of the most impressive qualities of fibreboard is its ability to cater to such a wide range of industries. From home decor projects to intricate structural applications, fibreboard plays an integral role in modern design and functionality.

1. Furniture Manufacturing

When it comes to dependable, budget-friendly furniture, manufacturers turn to fibreboard for its uniform quality and adaptability. Its smooth surface allows for easy veneering or laminating, making it a favorite for producing aesthetically appealing pieces. Whether it’s wardrobes, bookshelves, or kitchen cabinets, fibreboard offers both performance and cost-efficiency.

Statistics show that fibreboard accounts for up to 40% of materials used in mass-produced furniture globally, pointing to its dominance in the market.

2. Interior Design and Decor

Interior designers and architects frequently favor fibreboard for its versatility. MDF panels are often used to create wall paneling, intricate moldings, and decorative partitions that enhance interior aesthetics. Fibreboard is easily customizable, allowing artisans to paint, shape, and carve intricate designs.

For instance, MDF-based wall paneling has gained traction recently, with a 28% year-over-year increase in homeowner projects that integrate fiberboard for decorative purposes.

3. Flooring and Laminates

Fibreboard plays an essential role in modern flooring solutions, particularly laminate flooring. HDF, with its durability and moisture resistance, is frequently used as a core layer in laminate floors. Its ability to absorb sound and provide structural stability makes it a superior choice for residential and commercial properties.

Reports highlight that 60% of laminate flooring manufactured globally contains fibreboard as a core material, underlining its importance in the industry.

4. Construction Applications

Beyond furniture, fibreboard is a trusted material in construction. Its lightweight yet durable properties make it ideal for wall sheathing, subflooring, and insulation panels. Builders value it for its flexibility and sustainability compared to traditional plywood or drywall.

HDF, in particular, has seen widespread use in exterior applications where strength and moisture resistance are required. An industry study estimates that 1 out of 3 construction projects in urban areas incorporate fibreboard in some capacity.

Why Fibreboard is a Game-Changer

Several factors contribute to fibreboard’s reputation as a must-have material.

Sustainability at its Core

One of the most compelling aspects of fibreboard is its eco-friendly origins. Many manufacturers use recycled wood fibers from sawmills and other sources, cutting back on waste and promoting sustainable production practices.

According to Greenpeace, fiberboard reduces wood waste by 70% when compared to solid wood production, an eco-conscious approach this generation values.

Cost-Effectiveness

Fibreboard is celebrated for being both affordable and high-performing. Its production process is efficient and allows manufacturers to utilize lesser-grade wood fibers that would otherwise go to waste. For budget-conscious consumers and manufacturers alike, this cost-effectiveness is a strong selling point without compromising quality.

Consistent Strength and Durability

Since fibreboard is engineered, it offers unrivaled consistency in texture and density. Unlike natural wood, which may have knots or irregularities, fibreboard maintains strength and structure, ideal for high-precision applications.

Fibreboard & the Future

The demand for adaptable and sustainable materials is only set to grow with global housing needs and environmental concerns. Fibreboard appears to stay in the spotlight as the material of choice for innovative builders, designers, and consumers alike.

Emerging trends, such as eco-friendly housing and modular construction, signal a promising future for fibreboard. Renewable resources are increasingly significant to consumers and businesses, and the fibreboard industry is set to expand over the next decade.